Discover the traditional and complex process of producing henna powder, including the steps of harvesting the leaves, drying, sifting and sorting, blending, and packaging. Learn about the production of natural and blended henna products and find the best henna suppliers in India, including Sojat City Mehandi and Hennahub India

Henna is a natural dye that has been used for thousands of years for various purposes, including body art and hair coloring. It is made from the leaves of the henna plant (Lawsonia inermis) and is known for its reddish-brown color and nourishing properties. In this blog post, we will delve into the complete henna powder production process, from harvesting the henna leaves to producing the final product.

Harvesting the Henna Leaves

The first step in producing henna powder is harvesting the henna leaves. Henna plants are typically grown in hot, dry climates and are harvested several times a year. The leaves are picked when they are at their peak, as this is when they contain the highest concentration of the natural dye that is used to produce henna powder.

Drying the Henna Leaves

Once the henna leaves have been harvested, they are dried in the sun for several days. This step is important as it helps to preserve the color and potency of the henna. The dried leaves are then ground into a fine powder using a traditional mortar and pestle or a modern grinding machine.

Sifting and Sorting the Henna Powder

The next step in the henna powder production process is sifting and sorting the powder to remove any stems, twigs, or other impurities. This step is important to ensure that the final product is of high quality and is safe for use on the skin and hair. The henna powder is typically sorted using fine mesh screens, which remove any impurities and produce a uniform, high-quality product.

Blending the Henna Powder

Once the henna powder has been sorted, it is blended with other natural ingredients to produce a range of different henna products. For example, some henna products are blended with herbs, spices, and other natural ingredients to improve the color and texture of the henna paste. Other henna products are blended with ingredients such as lemon juice or tea to help the henna penetrate the hair or skin more effectively.

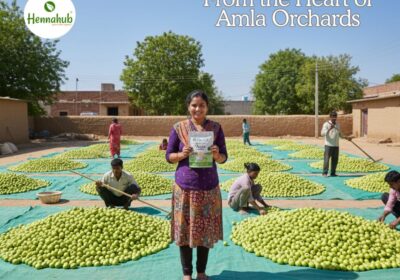

Packaging the Henna Powder

The final step in the henna powder production process is packaging the product for sale. Henna powder is typically packaged in airtight containers, such as jars or pouches, to preserve its quality and potency. The packaging should clearly state the type of henna powder (natural or blended) and any other relevant information, such as the ingredients used and any certifications that the product may have received.

In conclusion, the henna powder production process is a traditional and complex process that involves several steps to ensure that the final product is of high quality and is safe for use. From harvesting the henna leaves to packaging the final product, each step is carefully executed to produce a consistent and effective henna powder. Whether you are looking for natural henna powder or blended henna products, there are many reputable suppliers who can provide you with high-quality henna products that are safe and effective.

Hello hennahub.in administrator, Your posts are always well-written and easy to understand.